Grinding & Sorting Machine

ROCK SALT GRINDING PULVERIZER

This machine is used for very soft materials like sugar, salts chemicals, dyestuff etc. for medium fine to fine grinding. The material is centrally fed into the machine chamber. The grinding takes place between a high speed rotor consisting of a large number of pins and a stationery stator. The discharge takes place through the perforated screen at the bottom. The chamber is kept cool by circulating cool water through the built-in water jacket.

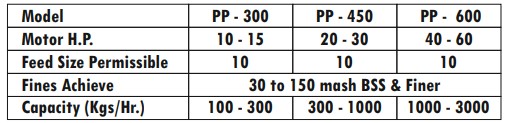

Specifications:

DELUMPER

Delumper has been specially designed for depluming & cutting various materials like foodstuffs, agro ayurvedic herbs, etc. into small pieces of powder content There required size with minimum no heat generation while grinding thereby retaining important properties like aroma taste, flavour & Colour. For Special applications are making crushed chillies for pizza toppings, chopped/minced/ granulated onions, tea-cut senna leaves, granulating of food colours, gum, asafetida, crushing of various Ayurvedic etc.

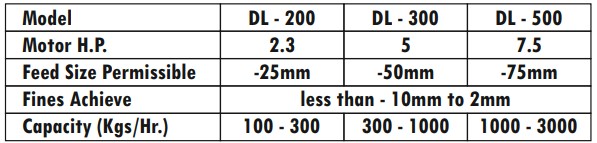

Specifications:

HAMMER CRUSHER

The most versatile machine that is used to grind almost all types of materials like spices, foodstuffs, chemicals ayurevedic herbals, minerals and other miscellaneous n materials. The grinding takes place between the high speed swinging hammers and top/side liners. Once the particle size reduces to that of the perforated/bartypescreen at the bottom. It will be discharged through the hopper. The fineness of the material can be changing the speed of rotor (hammer), content of serrations on liners, numbers of hammers and diameter of perforations on the controlled br y screen.

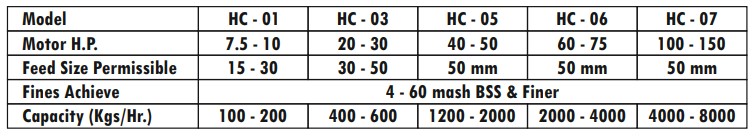

Specifications:

ULTRA FINE MILL

This is a screenless - pulveriser for grinding soft to medium hard materials into super-fine powder The Machine has a built-in water jacket to keep down the temperature in the machine chamber. The machine is generally used for super fine grinding of food dyes. industrial dyes, vat dyes, dyes intermediates, pharam drugs chemicals st. The feet is through a feeder strew that feeds material centrally into the machine chamber. The grinding takes place due to attrition between a high speed rotating rotor having six arms with wear resistant tips and side liners on both side of the tips of the tip and also a turbo effect. Hence this machine is sometime referred to turbo mill. The annular gap plate referred to materials through the mil. in other words it regulates the fineness of the materials. The powder is discharged through the bottom hopper.

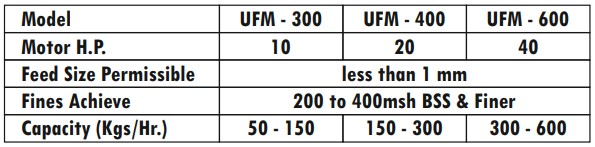

Specifications:

VIBRATORY SORTING SYSTEM

Leveraging on our vast industry experience and in depth domain knowledge of manufacturing and supplying an impressive assortment of Vibratory Sorting System; we are presenting Vibratory Sorting System to our valued clients. It finds its use in wide array of applications such as transfer tables, oiling tables, and washing tables and it is also extensively used as sorting equipment for conveyor, crusher, and bag opener. We follow stringent norms of quality and offer these at leading industry prices to our customers.

Specifications:

Size: 1000 mm X 600 mm

Special Design: As per requirement

Color: Green Material: Steel